NTE Process

Pneumatic Conveying and Air Pollution Control

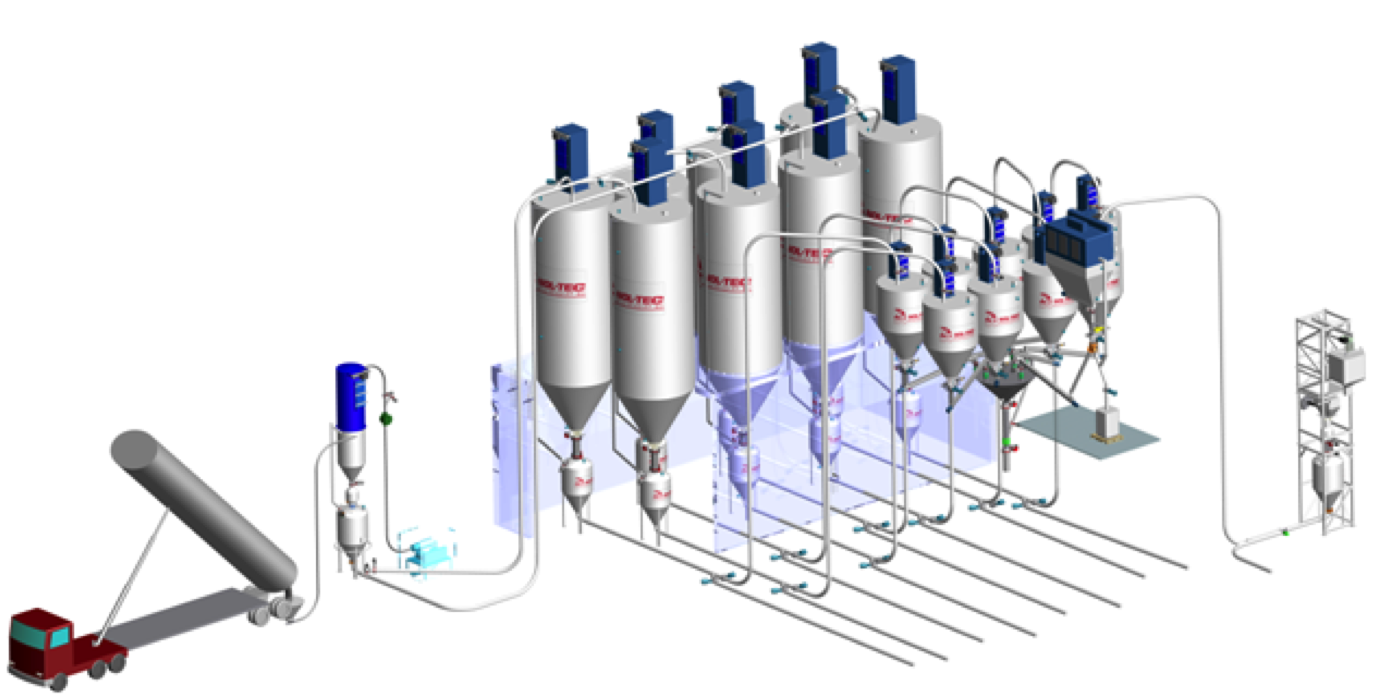

Together with environmental protection systems including Ash Handling Systems, DSI (Dry Sorebent Injection) patented Gas Cleaning Systems, Dust Collection Systems, Fabric Filters, Process Filtration Systems; Conversion of Electrostatic Filter to Bag Filter, Cyclones, Wet Scrubber Towers, Nol-Tec provides cutting edge solutions, spare parts and engineering service.

Being doctor of pneumatic systems Nol-Tec is able to overcome challenging projects. Nol-Tec has expertise in conveying different kind of materials such as soda, calcite and ash. The company offers tailor-made solutions to its customers. It provides solutions to the world's leading tire manufacturers on process and transportation of carbon black (Carbon Black Handling). Air pollution systems with Nol-Tec's DSI (Dry Sorbent Injection) Sorb-N-Ject technology designed for coal fired electrical generation facilities are practical alternatives for FGD. Nol-Tec's patented technology enable minimization of sulfur dioxide (SOx /SO2) emissions.

FIELDS OF ACTIVITY

Power and Energy Plants

Iron-Steel Industry

Chemical/Petrochemical Industry

Cement Industry

Foundry Industry

Copper Industry

Tire-Rubber Industry

Glass Industry

Food Industry

Environmental Industry

Animal Feed Industry

Pharma Industry

CORE BUSINESS

Dense Phase Conveying

The main objective of dense phase conveying systems is to avoid granular fracture of materials, and by preventing corrosion occuring in the pipes and elbows to transfer of the material in low speeds.

In this way the material is transported without change in grain structure, size and density besides, when the transported material and air ratio are compared, the amount of air used is minimum.

There are three different methods used for dense phase conveying:

Transport by Pressure vessel (transporter),

Transport by Cell feeders (rotary valve) using "slow flow" principle,

Vacuum dense phase transport

Dilute Phase (Dilute Phase) Conveying

The dilute phase conveying is characterized by low efficiency ratio which is lower than 5 kg product per 1 kg air at low conveying speeds. The dilute phase conveying can be performed through pressure (positive) or vacuum (negative) mode. It uses blower to generate air force. It is preferred more often for the cases where the conveying distance and the capacity are low.

Blending

Nol-Tec’s pneumatic blender was developed in the mid 80’s to answer the need for a valid alternative to remove the disadvantages of traditional mechanical blenders in fiberglass industry. The blending system being used primarily for this application is now commonly used to homogenize mixtures of various ingredients. Blender consists of aerators (nozzles) and control systems. The compressed air is injected from the aerator (nozzle), creates a circular motion moving the product from bottom to the top while blending and forms the mixture.

Dosing and Weighting

Nol-Tec Europe also deals with static and dynamic weighing systems. Static weighing is usually performed by loading cells mounted on silo supports. The stock and level information necessary for the process is provided in this way. The dynamic weighing systems are used in dosing belt weigher or decreasing weight weighing system (loss of weight) applications.

Control and Automation

Nol-Tec field and application experience is not limited to supplying pneumatic conveying systems but also includes the control and automation of those systems. This experience has been the basis for the establishment of Nol-Tec Automation and Service. Thus, the startup activities and system service is carried out by a specialized organization.

Please click the below link to enter the site:

www.nol-teceurope.com

- Catalogs / General Catalog

- Catalogs / Iron & Steel

- Catalogs / Energy

- Catalogs / Biyokütle & Çöp Yakma Tesisi

- Catalogs / Glass

- Catalogs / Food

- Presentations / Cement

- Auxiliary Products / Air Assist M366

- Auxiliary Products / Air Pad Brake Discharge Model 391 G/M

- Auxiliary Products / Bin Discharger M255

- Auxiliary Products / Blending Cone M244

- Auxiliary Products / Bulk Bag Loader M502

- Auxiliary Products / Bulk Bag Unloader Forklift Style M349

- Auxiliary Products / Bulk Bag Unloader Hoist Loading M348

- Auxiliary Products / Bulk Bag Unloader Forklift Style M358

- Auxiliary Products / Bulk Bag Unloader Hoist Loading M358

- Auxiliary Products / Cast Ceramic Lining Bend With Flanges M272 C-F

- Auxiliary Products / Cast Basalt Lining Bend With Flanges M272 B-F

- Auxiliary Products / Cast Basalt Lining Bend With Smooth End M272 B-PE

- Auxiliary Products / Cast Ceramic Lining Bend With Smooth End M272 C-PE

- Auxiliary Products / Ceramic Double Dısc Valve M508

- Auxiliary Products / Dust Collector Sıde Entry M238

- Auxiliary Products / Dust Collector Compact M323

- Auxiliary Products / Dust Collector M215

- Auxiliary Products / Dust Filter M275-279-317

- Auxiliary Products / Exhaust System Tanks Pressurized With Technology Nol-Tec

- Auxiliary Products / Flex Wall Batch Scale

- Auxiliary Products / Gravity Diverter M519

- Auxiliary Products / Hıgh Pressure Flexible Connector M243

- Auxiliary Products / Homogenize fluidizing Bin Bottom M328

- Auxiliary Products / Lump Breaker Double Shaft M503

- Auxiliary Products / LUMP Breaker Sıngle Shaft M503

- Auxiliary Products / Manuel Bag And Bulk Bag Dump M506 Combo

- Auxiliary Products / Minijet F.A M504

- Auxiliary Products / Minijet Tİ02 M504

- Auxiliary Products / Nol-Vac Transporter M394

- Auxiliary Products / Round Dust Collector M321

- Auxiliary Products / Top Removal Dust Collector M331

- Auxiliary Products / Two Ways Switch Diverter F PE M326

- Auxiliary Products / Two Way Switch Automatic Hose M405

- Auxiliary Products / Vacuum Filter Receiver M259

- Auxiliary Products / Two Ways Diverter with Ceramic Valve M326CV

- Auxiliary Products / ROUND DUST COLLECTOR_M321_M323

- Auxiliary Products / AIR ASSIST ECONOMIZER_M516

- Auxiliary Products / AERATOR_M276

- Auxiliary Products / ASH VALVE M419

- Auxiliary Products / BLENDER TRANSPORTER_M214

- Auxiliary Products / BULK BAG TENSIONING VALVE_M501

- Auxiliary Products / MANUAL BAG DUMP M506

- Auxiliary Products / MINIJET_M379

- Auxiliary Products / ROTOLENS VALVE_M517

- Auxiliary Products / SILO BLENDING CONE_M277

- Auxiliary Products / TRANSPORTER CONE 60° M201

- Auxiliary Products / TWO WAY PINCH DIVERTER F_PE_M403

- Auxiliary Products / Venturi Eductor M300 M320